Why We are Best in Industry

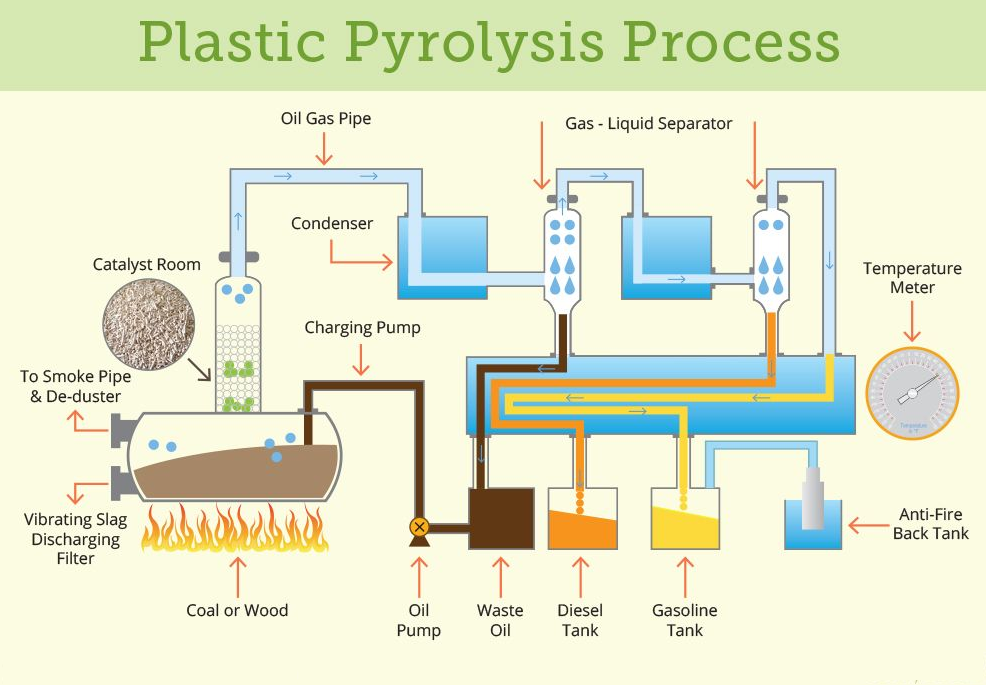

Plastics have become an indispensable part in today’s world, due to their lightweight, durability, and energy efficiency, coupled with a faster rate of production and design flexibility; these plastics are employed in entire gamut of industrial and domestic areas; hence, plastics have become essential materials and their applications in the industrial field are continually increasing. At the same time, waste plastics have created a very serious environmental challenge because of their huge quantities and their disposal problems. Waste plastic pyrolysis in liquid fuel (Petrol, Diesel oil, etc.) or chemical raw materials not only can effectively solve the problem of white pollution, but also can alleviate the energy shortage to a certain extent. Recycling of waste plastics is expected to become the most effective way. Waste plastics’ recycling, regenerating, and utilizing have become a hot spot of research at home and abroad and gradually formed a new industry

Creating Value from Waste

Klean Poly is focused on applying best-of-class green technologies that provide industrial energy solutions in a commercially viable and environmentally responsible manner. Our primary focus is on converting high calorific waste streams into valuable commodities which aid in the development and creation of the circular economy.

FOCUSED ON ENVIRONMENTAL CONSCIOUS INDUSTRIAL SOLUTIONS

As our name suggests, Klean Poly Tech Pvt Ltd. (as in “clean”) is an environmentally conscious industrial solutions company focused on providing clean energy and recovered resources to various industrial manufacturing sectors. We pay special attention to the implementation of resource-recovery and recycling solutions which aid in the development and creation of the circular economy we all want and need.

Klean poly Tech Pvt Ltd., is highly specialized in using advanced “clean” technologies to develop projects that provide environmentally beneficial solutions to energy production and waste-management challenges using only the best commercially available technologies .

Klean Poly Tech Pvt Ltd is committed to solving problems large and small in a commercially viable and environmentally responsible manner, with a primary focus on converting high calorific waste streams into valuable commodities.

Klean’s Mission & Mandate are to:

- To apply the best-of-class technologies to recover green energy and resources from waste Plastics

- To own/partner in facilities that deliver the highest possible returns both financially and environmentally,

- To own/partner and operate businesses that generate significant carbon credits from their operations,

- To produce and market high-quality commodities produced from waste that have a worldwide demand

Possible Plastics That Can Undergo Processing

waste plastic pyrolysis oil (WPPO) as an alternative fuel characterized in detail and compared with conventional diesel. High density polyethylene, HDPE, was pyrolyzed in a self-designed stainless steel laboratory reactor to produce useful fuel products. HDPE waste was completely pyrolyzed at 330–490°C for 2-3 hours to obtain solid residue, liquid fuel oil, and flammable gaseous hydrocarbon products. Comparison of the fuel properties to the petrodiesel fuel standards ASTM D 975 and EN 590 revealed that the synthetic product was within all specifications. Notably, the fuel properties included a kinematic viscosity (40°C) of 1.98 cSt, density of 0.75 gm/cc, sulphur content of 0.25 (wt%), and carbon residue of 0.5 (wt%), and high calorific value represented significant enhancements over those of conventional petroleum diesel fuel.